CUT & DRY

Space Saving Platform for Small Kitchen

Introducing CUT & DRY, it is a space saving and multi-purpose platform. A new way to live a minimal lifestyle in micro-apartments.

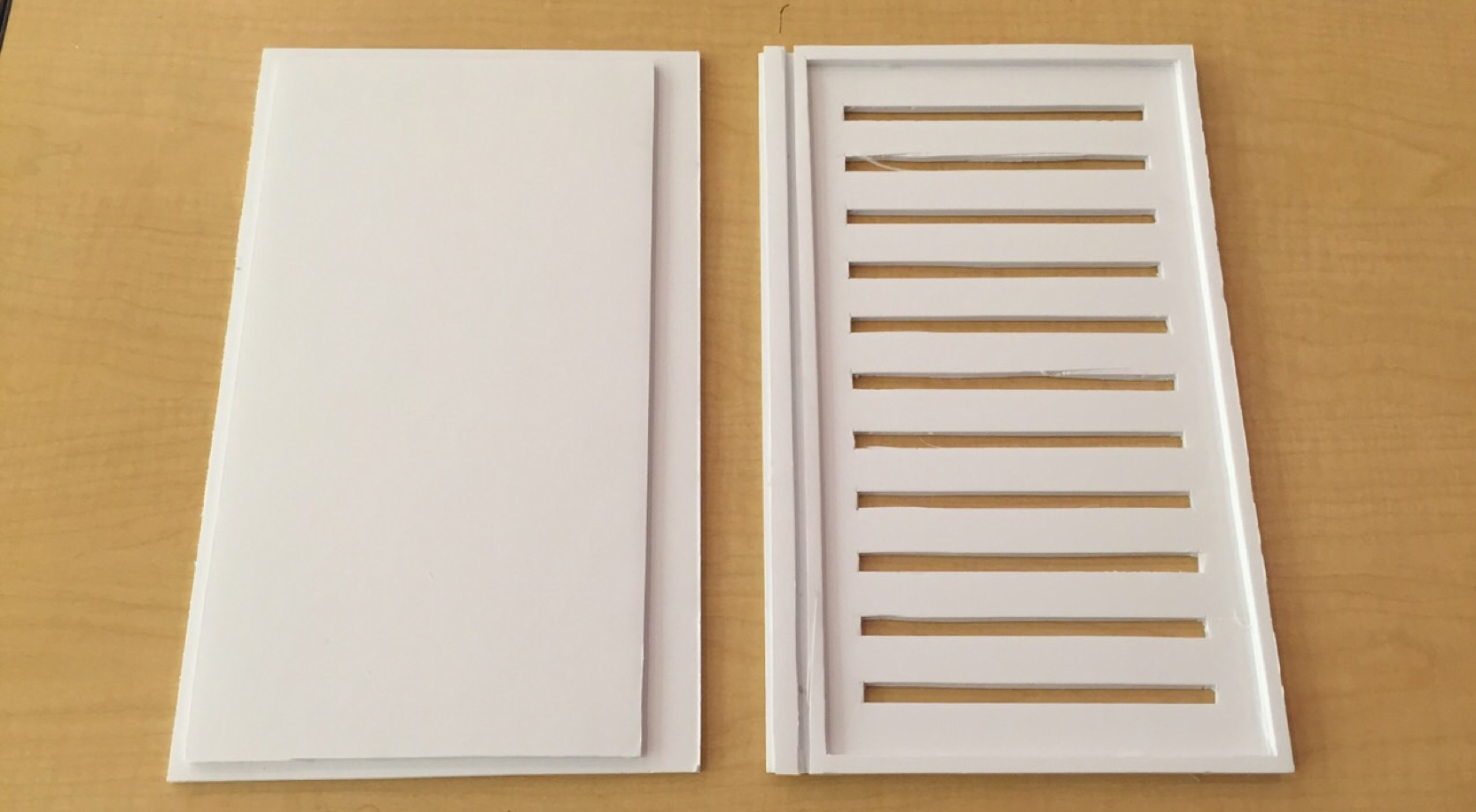

I live in small one bedroom apartment with my wife and a daughter. I cook a lot. But my kitchen is so tiny that I always struggle with preparing for foods and dish washing. So for this project, I aimed to design a simple kitchen product that is multi-functional. Considering different scenarios and behaviors in a micro kitchen, I designed a kitchenware that utilizes space efficiently, allowing people to do more in a small space. This platform consists of a cutting board for food preparation and dish drying rack. This two different product can be integrated to be utilized efficiently in tiny kitchen that most urban people have.

Successful Fundraised Kickstarter project

This product was launched and was successfully funded from Kickstarter I did with my friend Keith. The project was originally started from Entrepreneurial Design course (Advisor: Gary Chou, Christina Xu) in SVA's MFA Interaction Design program. During this project, I promoted and advertised this product with Twitter, Instagram accounts to get fund in Kickstarter.

HOW IT WORKS

CUT & DRY is created for people who have tiny kitchen space but love to cook. Now with CUT & DRY, a tiny kitchen space can do so much more. By utilizing half of the sink area, you can either dry dishes or simply place the chopping board to prepare food without making a mess.

DESIGN

CUT & DRY is a product handcrafted by Keith and I. Throughout the process, we keep asking ourselves what is the best solution? How can we make a product that is simple but multi-functional? Influenced by Naoto Fukasawa and Dieter Rams, we strive for affordance in the design concept so the product works with the subconscious behavior of people in a small kitchen.

And also, to give more meaningful experience and design to its users, we decided to engrave customer's name on the back side of the cutting board. As we mentioned already, CUT & DRY is a product handcrafted by us, Keith and I. We also engraved a limited edition number with backer's name. So when customer places the cutting board aside, their name and a limited edition number will proudly show that they are an early supporter.

BACKERS' REVIEWS

Development

$1,000 PROJECT

As a student in SVA's MFA Interaction, I took a course called Entrepreneurial Design. In this class, every student has to make $1,000 by designing their own product and using crowdfunding. Teaming up with another person was allowed so I teamed up with Keith. But we still had to make $1,000 each so our minimum goal for this project became $2,000 for our one project.

Christina is describing about $1,000 project.

HOW I STARTED

This project was started out based on my personal experience. I live in a one-bedroom apartment with my wife and one-year-old daughter in New Jersey. We cook at home almost everyday, however there is just not enough space. Dish drying rack takes up so much of that space. During food preparation, we have to place a cutting board partially over the sink area.

RESEARCH

By observing people living in New York City area, Our research insights proved that many people in urban areas faced the same problem. So we decided to improve kitchen experience by understanding their behaviors in a small space.

HYPOTHESIS

How might we turn a cutting board and a dish drying rack into one set so that those people can save space in their tiny kitchen?

ITERATION OF PROTOTYPING

1st prototype. Expandable platform

At first, my prototype was an expandable one that is not separable. This was a pretty simple and easy to use product. However, when I talked to people with this idea, I found a critical problem. People don't want to use one product for both chopping foods and drying dishes. If cutting something like meat, meat blood will be left and it is not so neat. It also can cause a virus.

2nd prototype. Standing cutting board

To improve the kitchen experience, I separated cutting board and drying rack. Also, I made a space where cutting board can be stood on top of drying rack so that back side of cutting board can be used for holding utensil and so on. This was a very multi functional set. However, the hole in the drying rack for making cutting board able to stand could easily get dirty. In kitchen area, a lot of sauces such as tomato sauces can be spilled inside the hole so that it becomes dirty. So we decided to go with another idea.

3rd prototype. Slidable drying rack

We decided to make the set more simple. So we removed the gap hole existed in the second iteration. In addition, we added a slider to drying rack that could be extended to fit various size of sink. But we found a problem that the slider is too slippery. When there were heavy dishes were put on the rack, it could not stand the weight.

Final Design

At last, Keith and I made a decision to make a cutting board and a drying rack separated in simple design. We deleted slider from the previous prototype. Instead, we decided to provided custom size to a certain people who has unique sink size.

PRODUCTION - HANDCRAFT PROCESS

CUT & DRY products are crafted with our own hand. We strongly believe that handcrafting makes our product much more valuable than mass-production.

SINGLE FORM PROCESS

Single process manufacturing on a piece of wood increased our production cost. However we strongly believe quality does matter, we aimed to create a product that can last much longer. CUT & DRY's foundational form-factor is processed on a CNC robotic milling machine for precise cutting. The product is designed to be shaped from a single piece of wood rather than attaching different scraps together.

HAND SANDING FOR ITS PERFECTION

We use various grades of sandpapers, from coarse to the finest. All sanding have to be done by hand along with the wood grains to ensure the best finishing.

WAXING AND OILING FOR FINAL FINISHING

We use high-quality food safe natural mineral oil, beeswax, carnauba wax for final finishing to ensure our product resists against water better and lasts for a long period of time.

THOUGHTS

This project helped me learn a lot about how to communicate with people and how to promote product using social accounts. Especially, I realized how cold email can be used powerfully when reaching out to people. With this tool, I could reach out to and talk to a OXO's kitchenware designer, 18F's designer, JosephJoseph's designer who I didn't know at all before. I could get a lot of know-how knowledge from them. Keith and I are talking about next step of this project, either making it a business or evolving the product into other design. I look forward to announce its next phase soon.